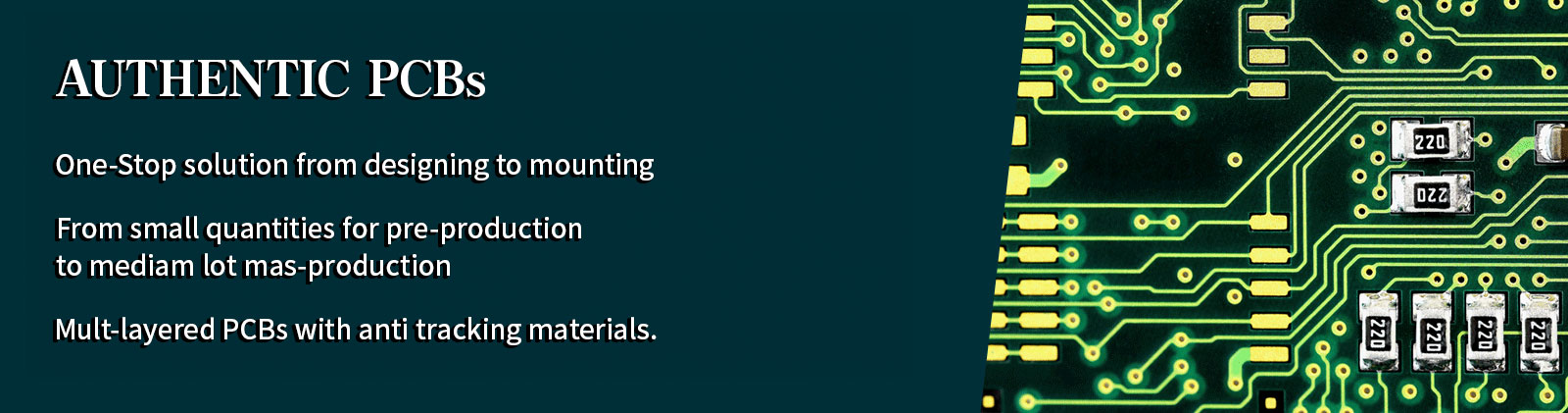

Uniquness of Daiwa’s PCB manufacturing

- One-Stop solution from designing to mounting

- From small quantities for pre-production to mediam lot mas-production

- Quick and accurate announcement of delivery schedule.

- Mult-layered PCBs with anti tracking materials.

- Scanning equipment enables re-production of PCBs from old films or PCBs.

- Comply with RoHS and UL.Capable to handle and manufacture halogen free PCBs

Manufactuing specs

Base material manufacturers

- ADEKA CORPORATION

- SUMITOMO BAKELITE Co.,Ltd.

- DENKA Co.,Ltd.

- Nan Ya Plastics Co.,Ltd.

- NIKKAN INDUSTRIES Co.,Ltd.

- NIPPON RIKA INDUSTRIES CORPORATION

- PANASONIC CORPORATION

- RESONAC CORPORATION

- RISHO KOGYO Co.,Ltd.

MATERIALS

| Material | FR-4 | Standard, High-Tg, CTI600,Halogen-Free | |||

|---|---|---|---|---|---|

| CEM-3 | Standard, High-Heat dissipation, CTI600 | ||||

| Metal | Cu(C1100, C1020),AL( A1050, A5052) | ||||

| Material thickness | 1&2 Layer | 0.2~3.2mm | 6 Layer | 0.8~3.2mm | |

| 4 Layer | 0.6~3.2mm | 8 Layer | 1.6~3.2mm | ||

| Cu-foil thickness | Standard material | 1 Layer | 35、70、105、140、175、210μ | ||

| 2 Layer | 18、35、70、105、140、175、210μ | ||||

| Multilayer | 12/35、18/35、35/35、35/70、70/70 | ||||

| Cu-plate | 200、300、400μ | ||||

SURFACE TREATMENT

| SURFACE TREATMENT | HASL:Pb, Pb free solder leveler, Flux Gold plating(ENIG), Bonding gold, etc. |

|---|

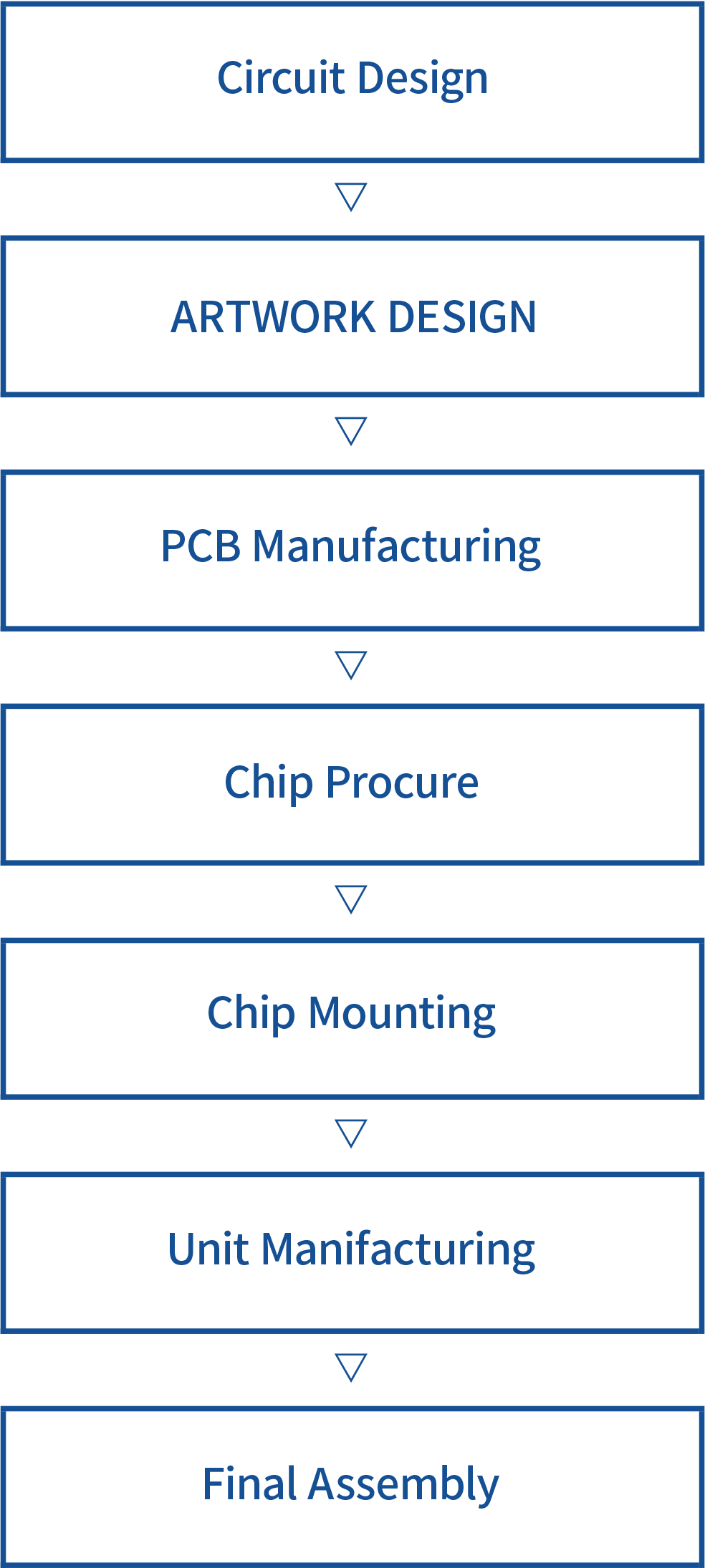

One-Stop solution from designing to mounting

(*including steps by external corporates)

Please feel free to contact for quick service for pre-production.

Wealthy experiences of PCB manufactuing that requires long term reliability.

-

Infrastructure -

Industrial equipment -

Medical equipment -

Car electronics

Since founding, we provided PCBs for various industries.

We have wealthy experiences of PCB manufactuing that requires long term reliability.

Our experiences and knowledges are the biggest reasons for our customers to choose us.