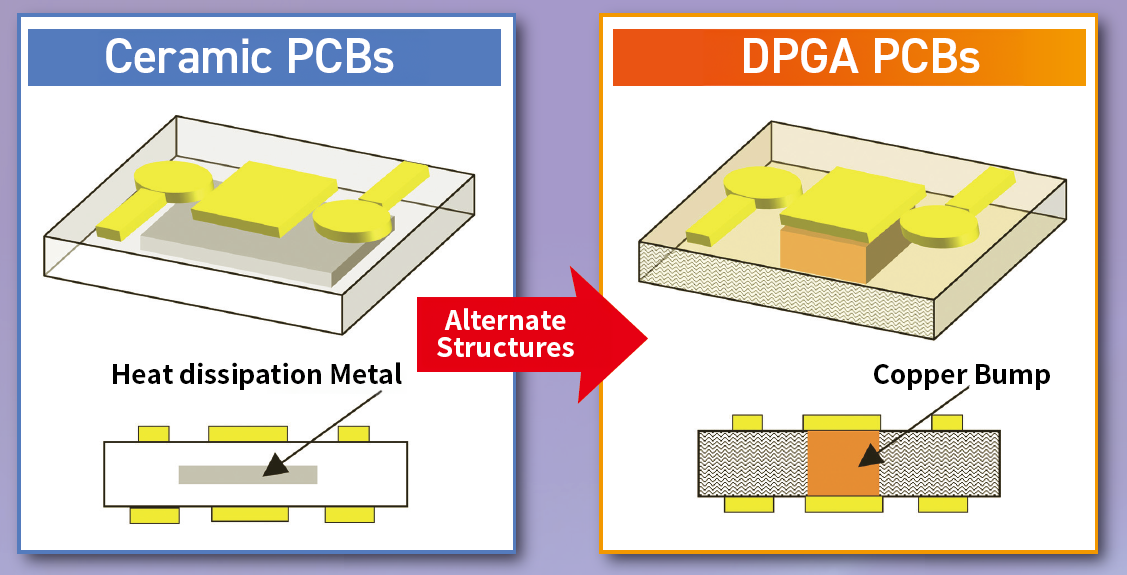

- REPLACEMENT FROM CERAMIC PCBs ENABLES THE COST REDUCTION

- REPLACEMENT FROM WATER-COOLED TO AIR-COOLED ENABLES THE UNIT COST REDUCTION

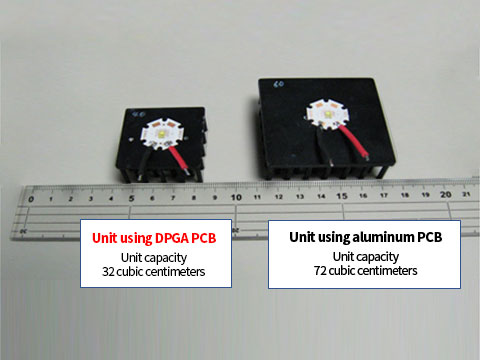

- REDUCTION OF HEAT SINK SIZE AND UNIT SIZE

- LOWER JUNCTION TEMPERATURE ENABLES THE LONGR LIFE OF THE UNIT

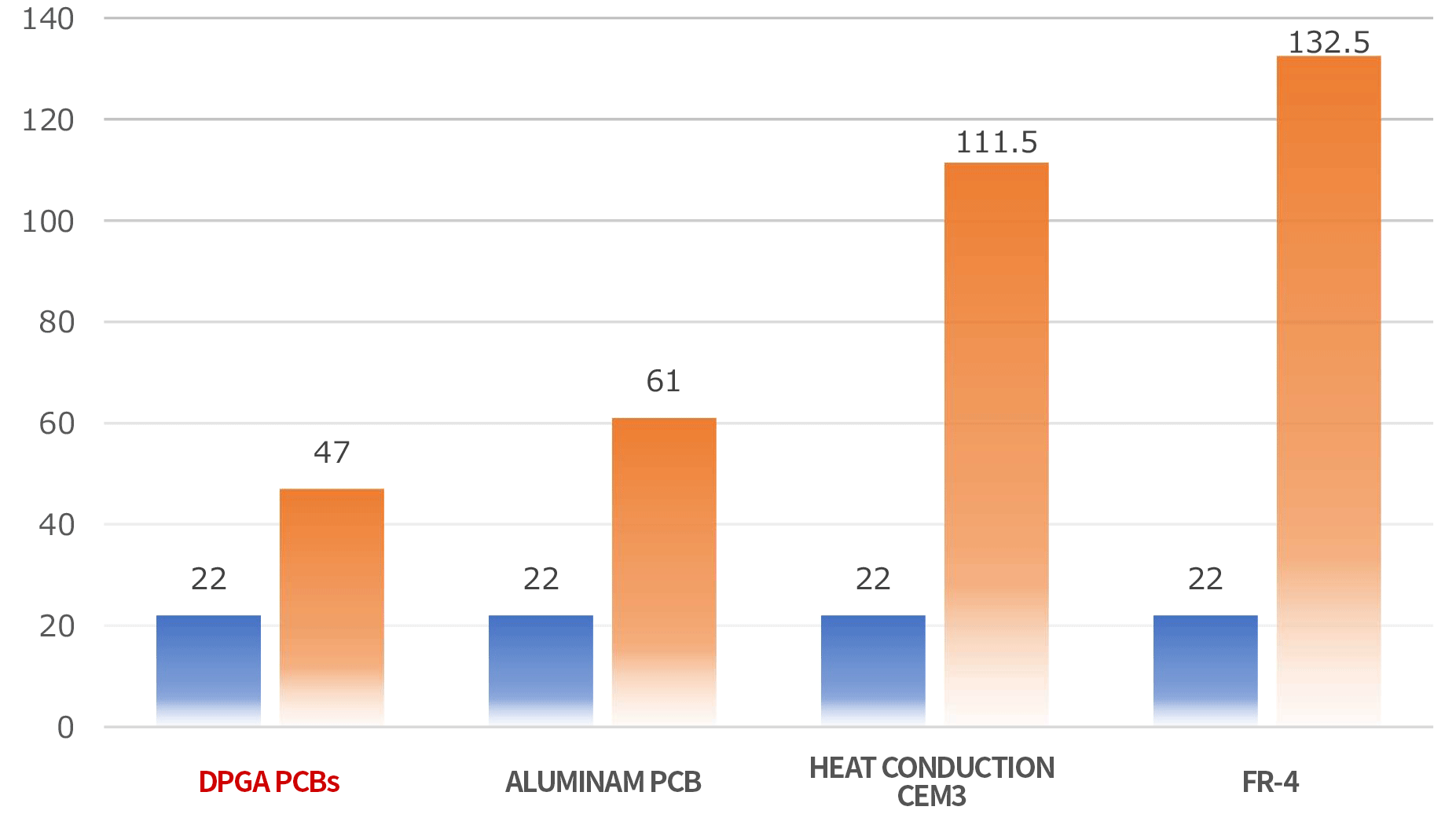

HEAT RADIATION PERFORMANCES – COMPARISON OF DPGA AND OTHERS –

HERE BELOW IS THE TESTING RESULT OF HEAT RADIATION

【CONDITIONS OF TESTING】

LED : REBEL (PHILIPS LUMILEDS)

WATTAGE : 3.4W

TEMPERATURE : 45MIN. AFTER TURNING THE LED ON (Celsius)

RESULT

| DPGA PCBs | ALUMINUM PCB | HEAT CONDUCTION CEM3 | FR-4 | |

|---|---|---|---|---|

| INITIAL TEMPERATURE | 22 | 22 | 22 | 22 |

| 45MIN. AFTER TURNING THE POWER ON(DEGREES CELSIUS) | 47 | 61 | 111.5 | 132.5 |

| TEMPERATURE RISE (DEGREES CELSIUS) | 25 | 39 | 89.5 | 110.5 |

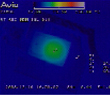

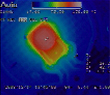

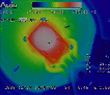

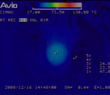

| THERMOGRAPHY AFTER 45MIN. |

|

|

|

|

DPGA PCBs

- INITIAL TEMPERATURE

- 45MIN. AFTER TURNING THE POWER ON(DEGREES CELSIUS)

- TEMPERATURE RISE (DEGREES CELSIUS)

- THERMOGRAPHY AFTER 45MIN.

ALUMINUM PCB

- INITIAL TEMPERATURE

- 45MIN. AFTER TURNING THE POWER ON(DEGREES CELSIUS)

- TEMPERATURE RISE (DEGREES CELSIUS)

- THERMOGRAPHY AFTER 45MIN.

HEAT CONDUCTION CEM3

- INITIAL TEMPERATURE

- 45MIN. AFTER TURNING THE POWER ON(DEGREES CELSIUS)

- TEMPERATURE RISE (DEGREES CELSIUS)

- THERMOGRAPHY AFTER 45MIN.

FR-4

- INITIAL TEMPERATURE

- 45MIN. AFTER TURNING THE POWER ON(DEGREES CELSIUS)

- TEMPERATURE RISE (DEGREES CELSIUS)

- THERMOGRAPHY AFTER 45MIN.

TENPERATURE RISE

(CLICK TO ENLARGE)

LESS THAN ONE THIRD OF RISE COMPARED WITH HEAT CONDUCTION CEM3

THEREFORE, ADVANTAGES BELOW CAN BE EXPECTED

HIGH RADIATION OF PCB ITSELF CAN :- REDUCTION OF HEAT SINK SIZE. LOWERING OF JUNCTION TEMPERATURE. HIGHER LUMINANCE AND LONGER LIFE.

REDUCTION OF HEAT SINK SIZE AND UNIT SIZE

THE CAPACITY CAN BE 44% USING DPGA

IN CASE THE LED TEMPERATURE IS 74 DEGREES CELSIUS

UNIT CAPACITY WITH DPGA PCB=32 CUBIC CENTIMETERS

UNIT CAPACITY WITH ALMINUM PCB=72 CUBIC CENTIMETERS

| PCB/UNIT CAPACITY | 18 CUBIC CENTIMETERS | 32 CUBIC CENTIMETERS | 50 CUBIC CENTIMETERS | 72 CUBIC CENTIMETERS |

|---|---|---|---|---|

| DPGA | 82 DEGREES CELSIUS | 73.4 DEGREES CELSIUS | 67.5 DEGREES CELSIUS | 64.7 DEGREES CELSIUS |

| ALUMINUM PCB | 95.7 DEGREES CELSIUS | 88 DEGREES CELSIUS | 80 DEGREES CELSIUS | 74.4 DEGREES CELSIUS |

| DIFFERENCE | 13.7 DEGREES CELSIUS | 14.6 DEGREES CELSIUS | 12.5 DEGREES CELSIUS | 9.5 DEGREES CELSIUS |

UNIT CAPACITY : 18 CUBIC CENTIMETERS

- DPGA

- 82 DEGREES CELSIUS

- ALUMINUM PCB

- 95.7 DEGREES CELSIUS

- DIFFERENCE

- 13.7 DEGREES CELSIUS

UNIT CAPACITY : 32 CUBIC CENTIMETERS

- DPGA

- 73.4 DEGREES CELSIUS

- ALUMINUM PCB

- 88 DEGREES CELSIUS

- DIFFERENCE

- 14.6 DEGREES CELSIUS

UNIT CAPACITY : 50 CUBIC CENTIMETERS

- DPGA

- 67.5 DEGREES CELSIUS

- ALUMINUM PCB

- 80 DEGREES CELSIUS

- DIFFERENCE

- 12.5 DEGREES CELSIUS

UNIT CAPACITY : 72 CUBIC CENTIMETERS

- DPGA

- 64.7 DEGREES CELSIUS

- ALUMINUM PCB

- 74.4 DEGREES CELSIUS

- DIFFERENCE

- 9.5 DEGREES CELSIUS

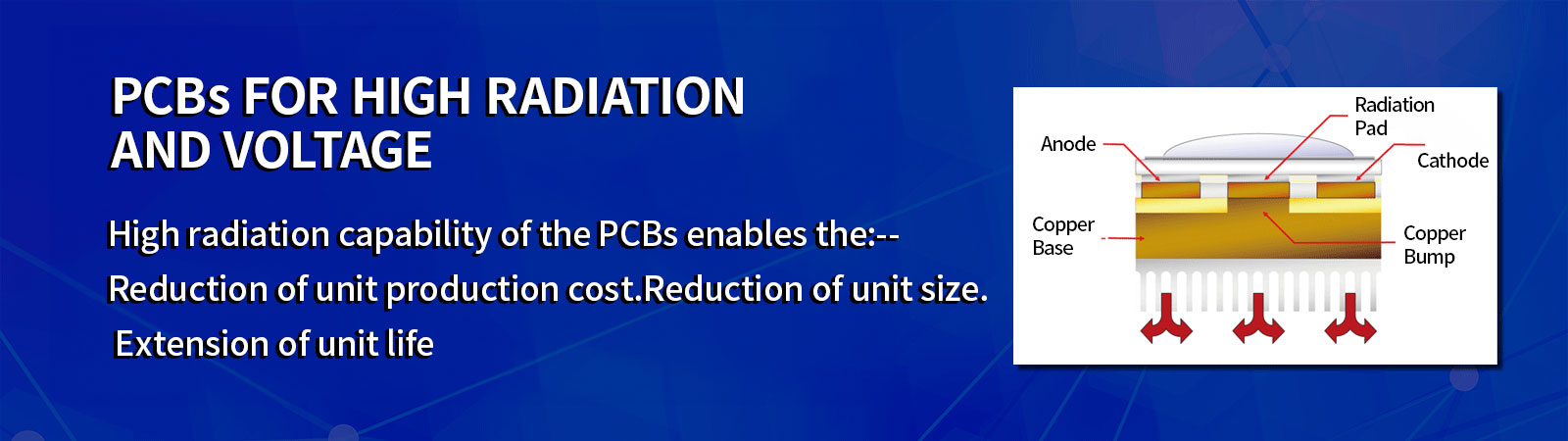

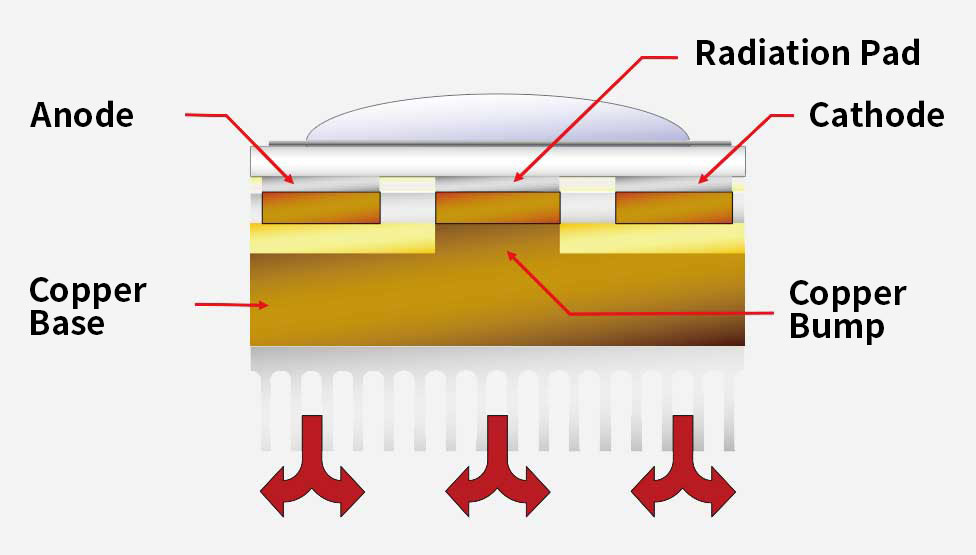

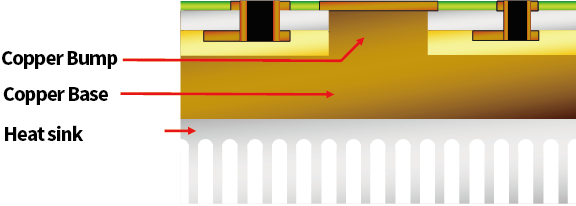

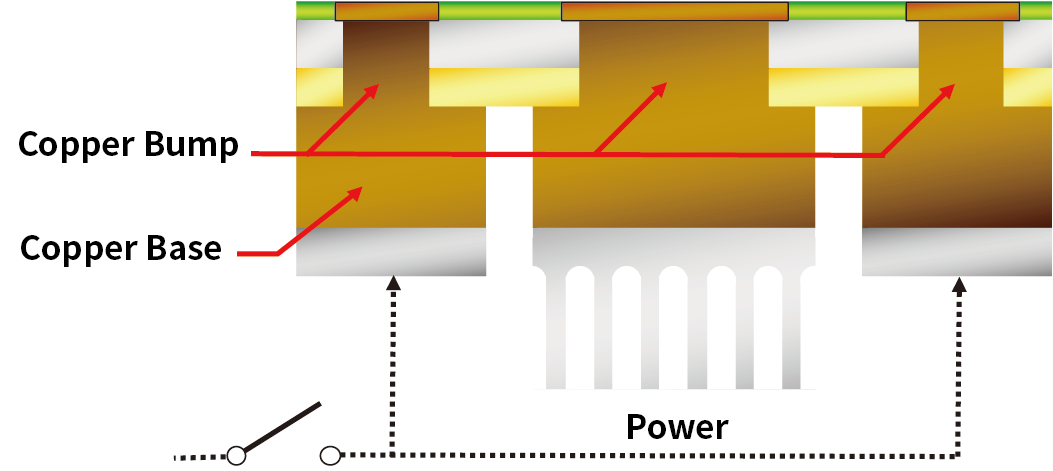

ARCHITECTURE AND FEATURES OF PATENTED DPGA PROCESS

THE DPGA STANDS FOR DAIWA PROCESS GLOVAL ADVANCE. THIS IS OUR OWN UNIQUE PROCESS THAT CAN ENABLE THE DIRECT CONNECTION TO COPPER BASES.

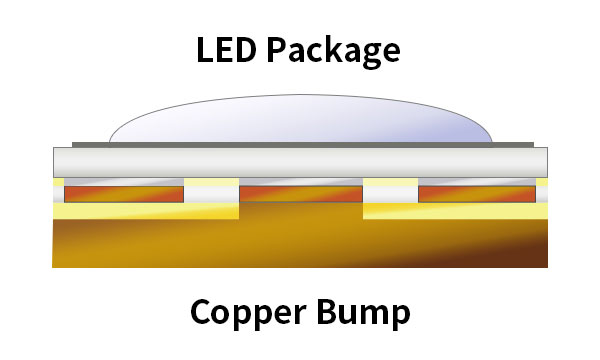

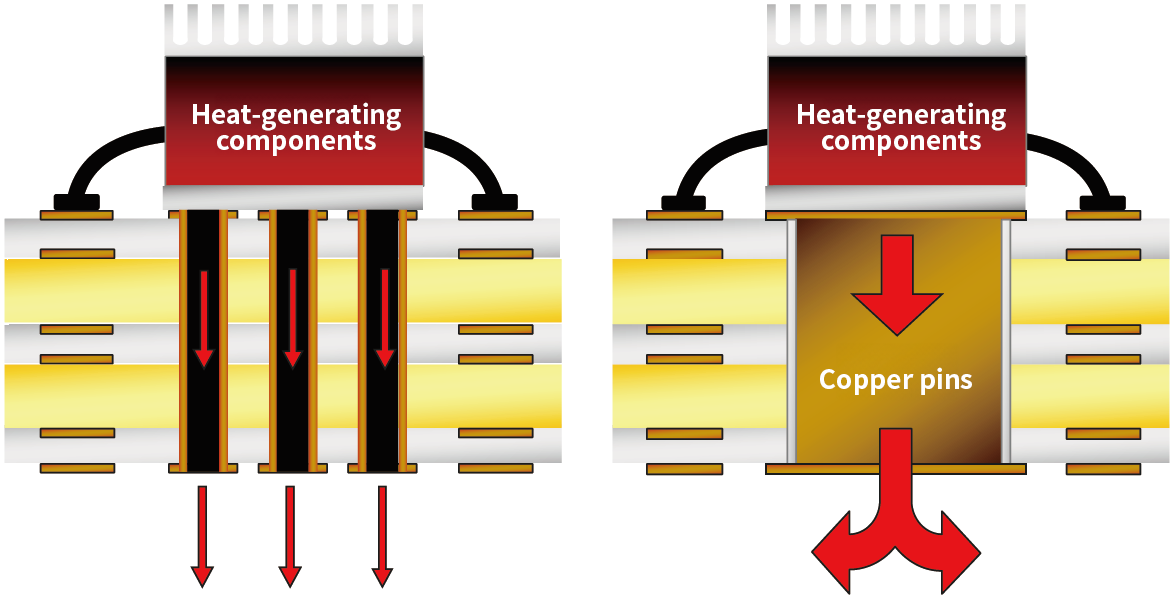

THE ARCHITECTURE THAT ENABLES THE HIGH HEAT RADIATION CAPABILITY (EXAMPLE WITH HIGH LUMINANCE LED)

DIRECT CONNECTION OF HEAT RADIATION PAD AND COPPER BASE VIA COPPER BUMP

HEAT CONDUCTION OF COPPER ENABLES THE HIGH HEAT RADIATION OF LED

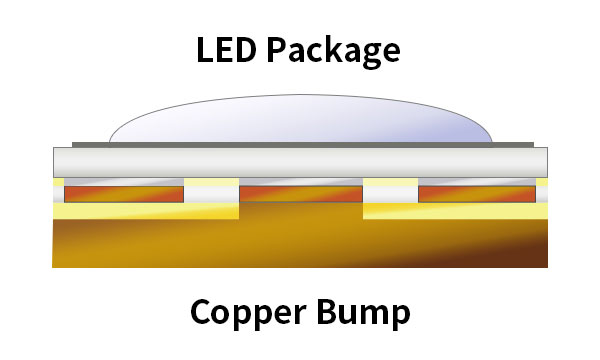

ARCHITECTURE DIFFERENCE

DIRECT CONNECTION OF DPGA IS THE BIGGEST DIFFERENCE FROM ALLUMINAM OR CEM3 PCBs

| DPGA PCBs | ALUMINUM PCB | HIGH CONDUCTION CEM3 OR FR-4 |

|---|---|---|

|

|

|

- DPGA PCBs

- ALUMINUM PCB

VARIATIONS IN ACCORDANCE WITH R&D NECESSITY

MULTI LAYERS ON METAL BASE

INSSULATION WITH SEPARATED COPPER BASE

REPLACEMENT OF CERAMIC BASED PCBs

COPPER PIN IN-LAY

CHIPS CAN BE MOUNTED ON BOTH SURFACES

PIN-POINT RADIATION OF HEAT RADIATION DEVICE

AS THIS IS NOT PRESS-FIT OF COPPER PINS, THERE IS NO CONCERNS ABOUT CRACKS OR REMAINING TOXIC

CONSULTATIONS OF COPPER PIN SIZE AND SHAPE IS POSSIBLE

FIVE FEATURES OF DPGA

- DIRECT CONNECTION ENABLES HIGH HEAT RADIATION AND HIGH CONNECTION RELIABILITY

- VARIOUS SIZES AND SHAPES COPPER BUMPS CAN BE CREATED

- MIXTURE OF DIFFERENT SIZE/SHAPED OF BUMPS IN ONE PCB IS POSSIBLE

- THIN, LIGHT WEIGHT AND STIFFNESS OF THE PCB

- MOST SUITABLE FOR LEDS AND IN-VHICLE PCBs

METAL BASED PCBs

WE CAN MANUFACTURE AUTHENTIC ALUMINUM OR COPPER BASED PCBs

THE HEAT CONDUCTION PERFORMANCE UPTO 10W

HIGH VOLTAGE PCBs(THICK COPPER)

THE THICK CUPPER CAN BE USED FOR BOTH SURFACE AND/OR INNER LAYERS